Whirl-Air systems smoothly and efficiently transport ingredients and raw materials from bulk supply to in-plant processing destinations.

Whirl-Air designs, engineers, and manufactures complete control systems for operating your bulk material handling system.

Whirl-Air boasts a fully functional test lab facility, featuring dense and dilute conveying as well as air blending. This allows us to determine how products of varying consistencies will behave.

Whirl-Air field technicians can oversee your project through installation, start-up and run-in. As your needs change, Whirl-Air can help reconfigure your system for new products, rates, and configurations.

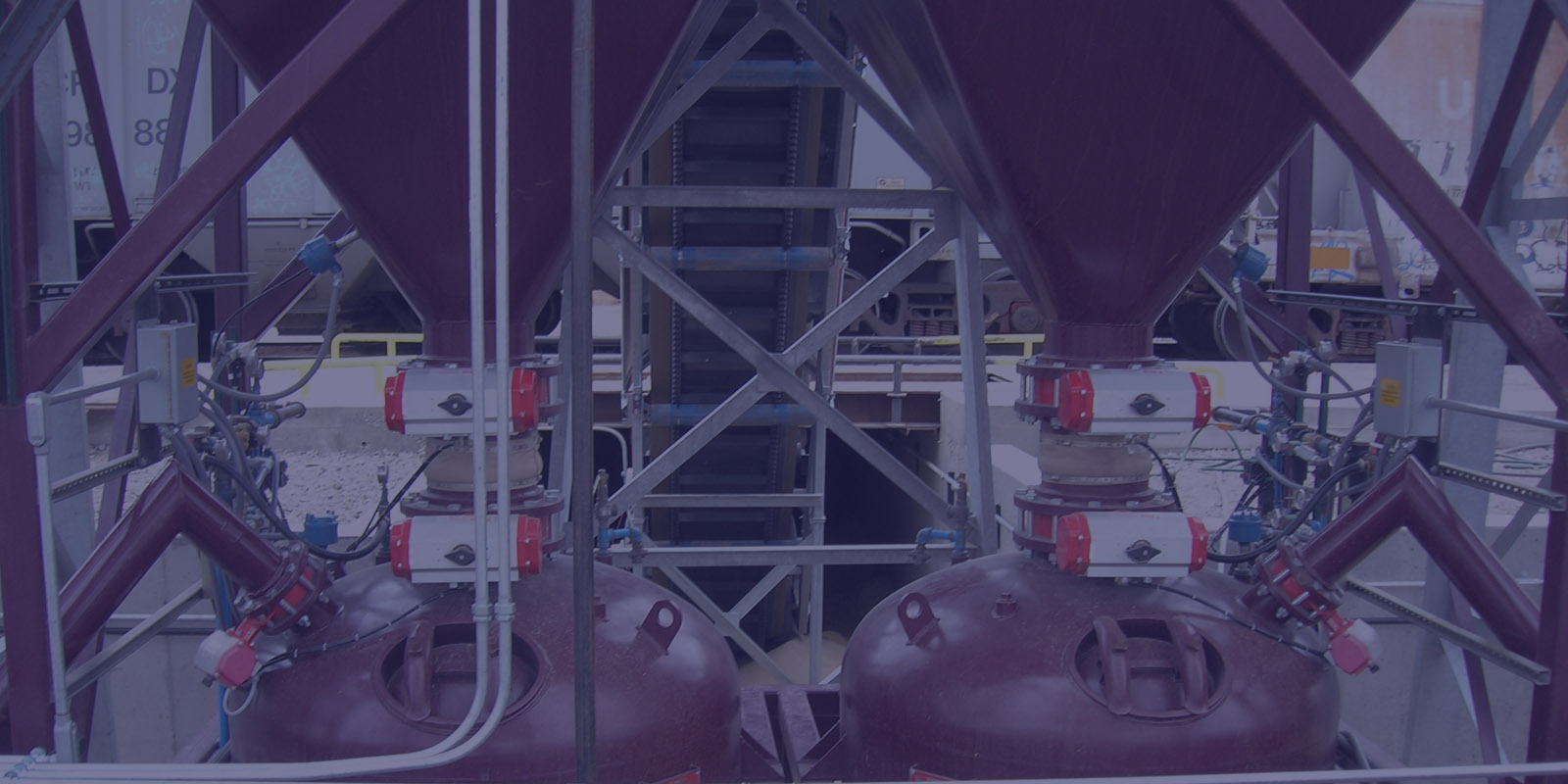

Whirl-Air provides fabrication and assembly of code vessels, specialty tanks, support structure and periphery equipment. In addition, we provide custom machining and heat stress relieving.